Researchers at Carnegie Mellon University have reduced the cost of 3D Bioprinters significantly.

Photo:Bigstock.com

A cell phone protector, a spoon or a key ring can now be printed three-dimensionally at home; Equipment and materials are no longer as expensive as they were a few years ago. However, there is some specialized equipment at almost unattainable prices. Such is the case of 3D bioprinters that model objects with fluids that researchers hope someday will print human organs.

Conventional 3D printers work with melted plastic filaments. Its cost varies, and printers manufactured in China are as inexpensive as 300 dollars. On the other hand, the price of commercial 3D printers with syringe pump extruders ranges between 10,000 and 200,000 thousand dollars; they are not modifiable, and their design is protected by copyright.

This type of syringe-pump-based 3D printers are used to print food, create embedded applications in objects, and prostheses for medical use. Researchers have the aim of developing a 3D machine capable of printing organs and tissues of the human body from fluids created with cells.

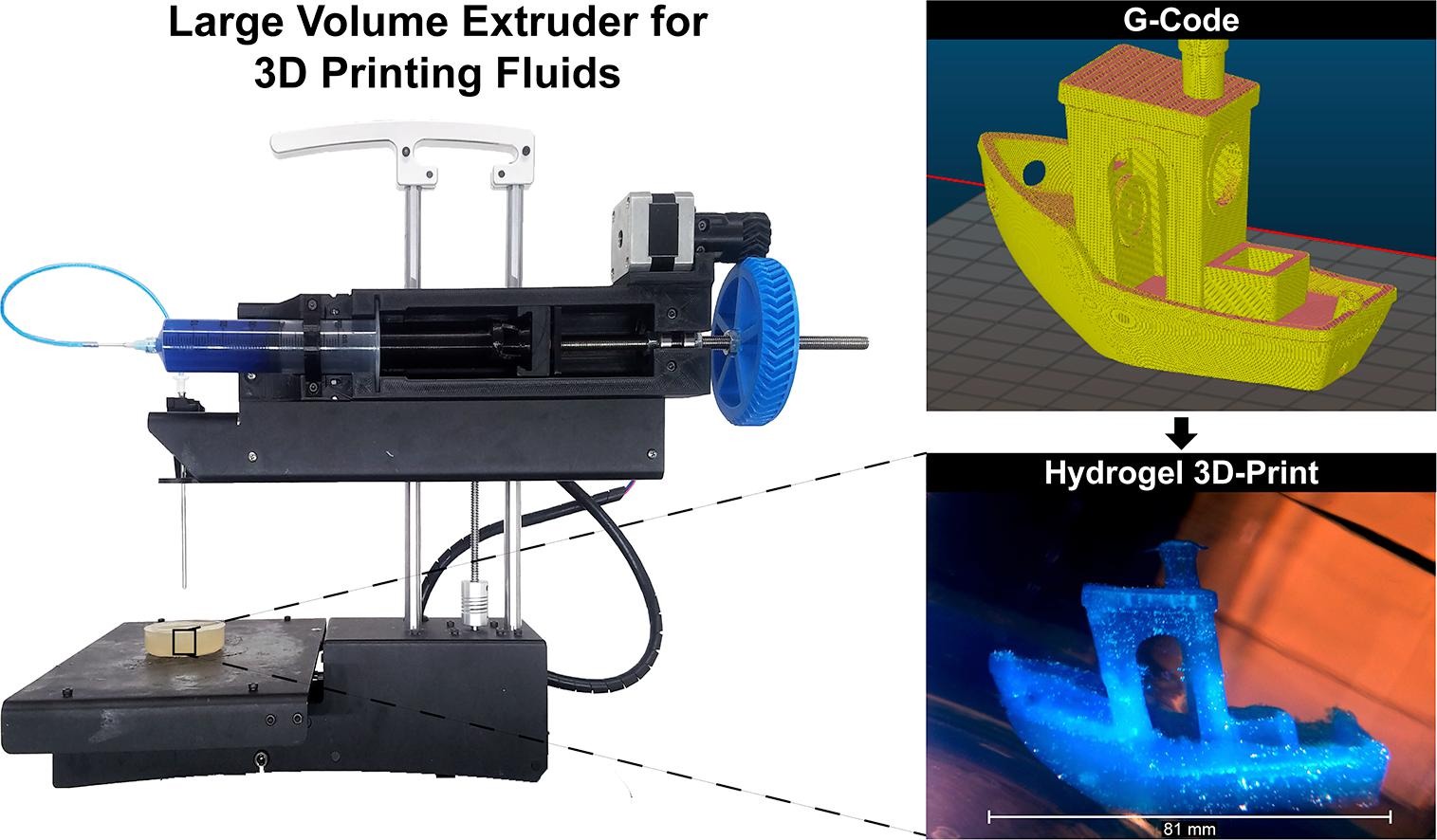

Recently a couple of scientists from Carnegie Mellon University, published a design, under the Creative Commons (CC) licenses, with which anyone can transform a low-cost 3D printer into a bioprinter through an accessory that can be manufactured with only 49.27 dollars. They presented the results of their research, in addition to sharing instructions and tutorials to start experimenting with 3D bioprinting.

Called Large Volume Extruder (LVE), this syringe-pump-based system is compatible with open source 3D printers. The design uses a standard 60 ml syringe as a reservoir, has high-speed movement capabilities, and can print fluids as small as 100 micrometers. This system has the purpose of printing biopolymers, hydrogels, pastes, epoxies and other liquids.

Reducing the cost, sharing knowledge and promoting these technologies will allow more researchers to develop useful applications for medical purposes. We look forward to the first impressions of human organs.

This article from Observatory of the Institute for the Future of Education may be shared under the terms of the license CC BY-NC-SA 4.0

)

)

)

Nohemí Vilchis

Nohemí Vilchis

Nohemí Vilchis